Izinto eziluncedo kunye nokungalunganga kweCOB epakishwe isikrini se-LED kunye nobunzima bayo bophuhliso

Ngenkqubela phambili eqhubekayo yeteknoloji yokukhanyisa i-slid-state, i-COB (i-chip ebhodini) iteknoloji yokupakisha ifumene ingqalelo engakumbi nangakumbi.Njengoko umthombo wokukhanya we-COB uneempawu zokumelana ne-thermal ephantsi, ukuxinana okukhanyayo okukhanyayo, ukukhanya okuncinci, kunye nokukhutshwa okufanayo, isetyenziswe ngokubanzi kwizibane zokukhanyisa ngaphakathi nangaphandle, ezifana nesibane esisezantsi, isibane sebhalbhu, ityhubhu ye-fluorescent, isibane sesitrato, kunye nesibane semizi-mveliso nesemigodini.

Eli phepha lichaza iingenelo zokupakishwa kweCOB xa kuthelekiswa nokupakishwa kwe-LED yemveli, ikakhulu kwimiba emithandathu: iingenelo zethiyori, izibonelelo zokuvelisa, inzuzo ephantsi yokumelana ne-thermal, izibonelelo zomgangatho wokukhanya, izibonelelo zesicelo, kunye nezibonelelo zeendleko, kwaye ichaza iingxaki ezikhoyo zobuchwepheshe beCOB. .

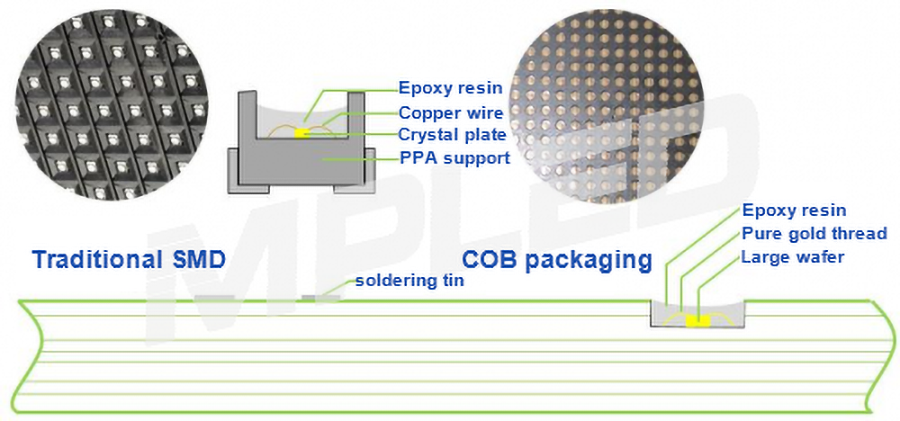

Umahluko phakathi kokupakishwa kweCOB kunye nokupakishwa kwe-SMD

Iingenelo zethiyori zeCOB:

1. Ukuyila kunye nophuhliso: ngaphandle kobubanzi bomzimba wesibane esisodwa, ingaba yincinci kwithiyori;

2. Inkqubo yobuchwephesha: ukunciphisa iindleko ze-bracket, ukwenza lula inkqubo yokuvelisa, ukunciphisa ukuchasana kwe-thermal ye-chip, kunye nokufezekisa ukupakisha okuphezulu;

3. Ufakelo lobunjineli: Ukusuka kwicala lesicelo, imodyuli ye-COB ye-LED ye-COB inokubonelela ngokufanelekileyo kunye nokukhawuleza kofakelo lokufakela abavelisi becala lesicelo sokubonisa.

4. Iimpawu zeMveliso:

(1) Ukukhanya kwe-Ultra kunye nencinci: iibhodi ze-PCB ezinobunzima ukusuka kwi-0.4-1.2mm zingasetyenziswa ngokweemfuno zabathengi zokunciphisa ubunzima ubuncinane kwi-1/3 yeemveliso zemveli zemveli, ezinokunciphisa kakhulu isakhiwo. , iindleko zokuhamba kunye nobunjineli kubathengi.

(2) Ukumelana nokungqubana kunye nokumelana nokunyanzeliswa: Iimveliso ze-COB zifakela ngokuthe ngqo iitshiphusi ze-LED kwindawo ye-concave yesibane kwiibhodi ze-PCB, kwaye emva koko zidibanise kwaye ziqinise nge-epoxy resin adhesive.Umphezulu weendawo zesibane uphakanyiselwe kwindawo engqukuva, egudileyo, eqinile, iyaxhathisa impembelelo kunye nokunganxibi.

(3) I-engile enkulu yokujonga: i-engile yokujonga ingaphezulu kwe-175 degrees, kufutshane ne-180 degrees, kwaye inombala ophucukileyo wokukhanya owenziwe ngodaka.

(4) Ukukwazi ukutshabalalisa ubushushu obunamandla: Iimveliso ze-COB zifakela isibane kwi-PCB, kwaye zigqithise ngokukhawuleza ubushushu bombane wesibane kwi-foil yobhedu kwi-PCB.Ubukhulu befoyile yobhedu yebhodi yePCB ineemfuno zenkqubo engqongqo.Ngokudityaniswa kwenkqubo yokubekwa kwegolide, akunakufane kubangele ukuthomalalisa ukukhanya okukhulu.Ke, zimbalwa izibane ezifileyo, zandisa kakhulu ubomi bomboniso we-LED.

(5) Ukunxiba ukuxhathisa, ukucoceka kulula: umphezulu ogudileyo kunye nolukhuni, ukuxhathisa impembelelo kunye nokungagugi;Akukho maski, kwaye uthuli lunokucocwa ngamanzi okanye ngelaphu.

(6) Zonke iimpawu ezintle zemozulu: unyango lokukhuselwa kathathu luyamkelwa, olubalaseleyo lwamanzi, umswakama, ukubola, uthuli, umbane ongatshintshiyo, i-oxidation kunye nemiphumo ye-ultraviolet;Iyakwazi ukuhlangabezana neemeko zokusebenza zemozulu yonke, kunye nemekobume yomahluko wobushushu ukusuka kwi-30℃ukuya kwi-80℃isenokusetyenziswa ngokuqhelekileyo.

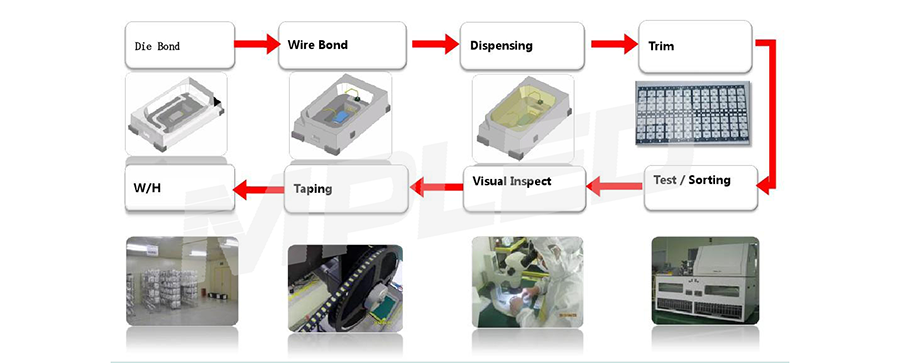

Intshayelelo yeNkqubo yokuPakisha i-COB

1. Iingenelo ekusebenzeni kakuhle kwemveliso

Inkqubo yokuvelisa i-COB yokupakisha ngokusisiseko iyafana naleyo ye-SMD yendabuko, kwaye ukusebenza kakuhle kwe-COB yokupakisha ngokusisiseko kuyafana nokupakishwa kwe-SMD kwinkqubo yocingo oluqinileyo lwe-solder.Ngokumalunga nokusabalalisa, ukuhlukana, ukusabalalisa ukukhanya kunye nokupakisha, ukusebenza kakuhle kwe-COB yokupakisha kuphezulu kakhulu kuneemveliso ze-SMD.Iindleko zabasebenzi kunye nokuveliswa kwe-akhawunti ye-SMD yokupakisha yendabuko malunga ne-15% yeendleko eziphathekayo, ngelixa iindleko zabasebenzi kunye nokuvelisa i-akhawunti yokupakisha ye-COB malunga ne-10% yeendleko eziphathekayo.Ngokupakishwa kweCOB, iindleko zabasebenzi kunye nezokuvelisa zingagcinwa nge-5%.

2. Izinto eziluncedo zokumelana ne-thermal ephantsi

Inkqubo yokumelana ne-thermal yezicelo zokupakisha ze-SMD zemveli yile: i-chip - i-crystal adhesive eqinile - i-solder joint - i-solder paste - i-foil yobhedu - insulating layer - i-aluminium.Ukumelana ne-thermal ye-COB yokupakisha inkqubo yile: i-chip - i-crystal adhesive eqinile - i-aluminium.Inkqubo yokumelana ne-thermal yephakheji ye-COB iphantsi kakhulu kune-package ye-SMD yendabuko, ephucula kakhulu ubomi be-LED.

3. Iinzuzo zomgangatho wokukhanya

Kwipakethe yemveli ye-SMD, izixhobo ezininzi ezidityanisiweyo zincanyathiselwa kwi-PCB ukwenza izinto zomthombo wokukhanya kwizicelo ze-LED ngendlela yeepatches.Le ndlela ineengxaki zokukhanya kwamabala, ilitha kunye neghosting.Iphakheji ye-COB yiphakheji edibeneyo, engumthombo wokukhanya ongaphezulu.Umbono mkhulu kwaye kulula ukulungelelanisa, ukunciphisa ukulahlekelwa kwe-refraction yokukhanya.

4. Iinzuzo zesicelo

Umthombo wokukhanya we-COB uphelisa inkqubo yokunyuka kunye nokubuyisela kwakhona i-soldering ekupheleni kwesicelo, kunciphisa kakhulu inkqubo yokuvelisa kunye nemveliso ekupheleni kwesicelo, kwaye igcina izixhobo ezihambelanayo.Iindleko zemveliso kunye nezixhobo zokuvelisa ziphantsi, kwaye ukusebenza kakuhle kwemveliso kuphezulu.

5. Iinzuzo zeendleko

Ngomthombo wokukhanya we-COB, iindleko zeskimu sesibane se-1600lm sinokuncitshiswa nge-24.44%, iindleko zeskimu sesibane sonke se-1800lm sinokuncitshiswa ngama-29%, kunye neendleko zeskimu sesibane se-2000lm sinokuncitshiswa ngama-32.37%.

Ukusebenzisa umthombo wokukhanya we-COB uneenzuzo ezintlanu ngaphezu kokusebenzisa umthombo wokukhanya wephakheji ye-SMD yendabuko, enenzuzo enkulu ekusebenzeni komthombo wokukhanya, ukumelana nokushisa, umgangatho wokukhanya, isicelo kunye neendleko.Iindleko ezibanzi zingancitshiswa malunga ne-25%, kwaye isixhobo silula kwaye sikulungele ukusisebenzisa, kwaye inkqubo ilula.

Imiceli mngeni yobugcisa yeCOB yangoku:

Okwangoku, ukuqokelelwa kweshishini leCOB kunye neenkcukacha zenkqubo kufuneka ziphuculwe, kwaye ijongene neengxaki zobugcisa.

1. Ireyithi yokupasa yokuqala yokupakishwa iphantsi, ukuchasana kuphantsi, kwaye iindleko zokugcinwa ziphezulu;

2. Umbala wayo wokunikezela ngokufana ungaphantsi kakhulu kunelo lomboniso weskrini ngasemva kwetshiphu ye-SMD enokukhanya kunye nokwahlulwa kombala.

3. Ukupakishwa kwe-COB ekhoyo kusetyenziswa i-chip esemthethweni, efuna i-crystal eqinile kunye nenkqubo yokudibanisa ucingo.Ngoko ke, kukho iingxaki ezininzi kwinkqubo yokudibanisa ucingo, kwaye ubunzima benkqubo buhambelana ngokungafaniyo nommandla wepad.

4. Iindleko zokwenziwa kwemveliso: ngenxa yezinga eliphezulu elineziphene, ixabiso lokuvelisa liphezulu kakhulu kunesithuba esincinci se-SMD.

Ngokusekelwe kwizizathu ezingentla, nangona iteknoloji ye-COB yangoku yenze inkqubela phambili kwibala lokubonisa, akuthethi ukuba iteknoloji ye-SMD ihoxise ngokupheleleyo ekunciphiseni.Kwintsimi apho i-point spacing ingaphezulu kwe-1.0mm, iteknoloji yokupakisha ye-SMD, kunye nokusebenza kwayo kwemveliso ekhulileyo kunye nokuzinza, umkhuba wokuthengisa obanzi kunye nenkqubo yokuqinisekisa yokufakela kunye nokugcinwa ngokugqibeleleyo, kuseyona indima ehamba phambili, kwaye ikwayeyona nto ifanelekileyo yokukhetha. isikhokelo kubasebenzisi kunye nemarike.

Ngophuculo oluthe ngcembe lobuchwepheshe bemveliso yeCOB kunye nokuvela ngakumbi kwemfuno yentengiso, usetyenziso olukhulu lwetekhnoloji yokupakisha ye-COB iya kubonisa iingenelo zayo zobugcisa kunye nexabiso kuluhlu lwe-0.5mm ~ 1.0mm.Ukuboleka igama kwishishini, "i-COB yokupakisha ilungiselelwe i-1.0mm nangaphantsi".

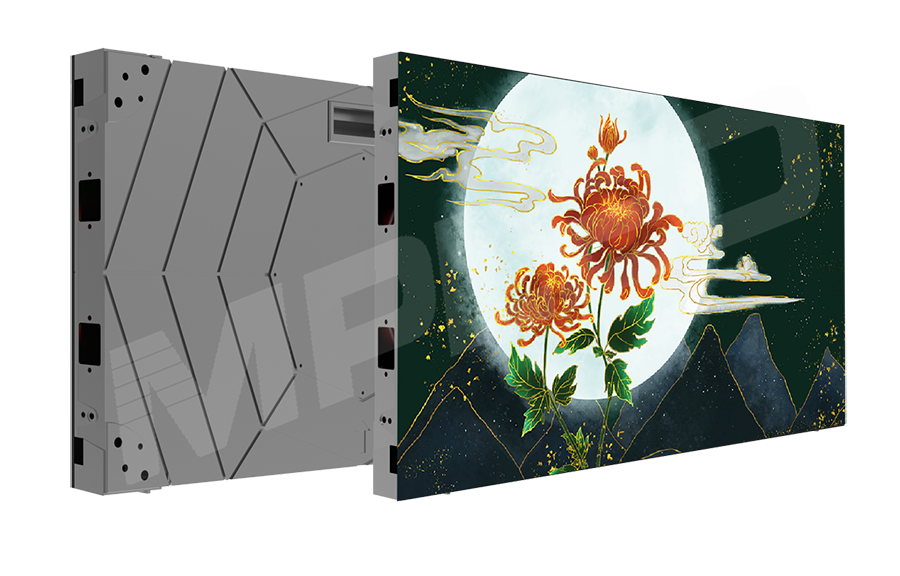

I-MPLED inokukunika umboniso we-LED wenkqubo yokupakisha ye-COB, kunye ne-ST yethu Piimveliso ze-ro zingabonelela ngezisombululo ezinjalo. Isikrini somboniso we-LED esigqitywe yinkqubo yokupakishwa kwe-cob sinesithuba esincinci, esicacileyo kunye nomfanekiso obuthathaka ngakumbi.I-chip ekhupha ukukhanya ipakishwe ngokuthe ngqo kwibhodi ye-PCB, kwaye ubushushu buchithwa ngokuthe ngqo ngebhodi.Ixabiso lokumelana ne-thermal lincinci, kwaye ukutshatyalaliswa kobushushu kunamandla.Isibane esingaphezulu sikhupha ukukhanya.Imbonakalo engcono.

ST Pro series

Ixesha lokuposa: Nov-30-2022